SWF-590 Automatic Flow Wrapping Packaging Machine

- group name

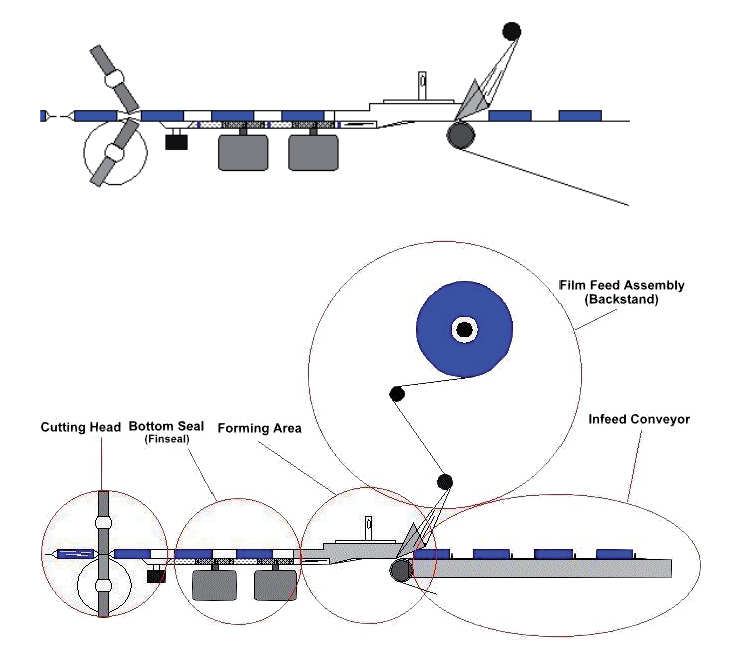

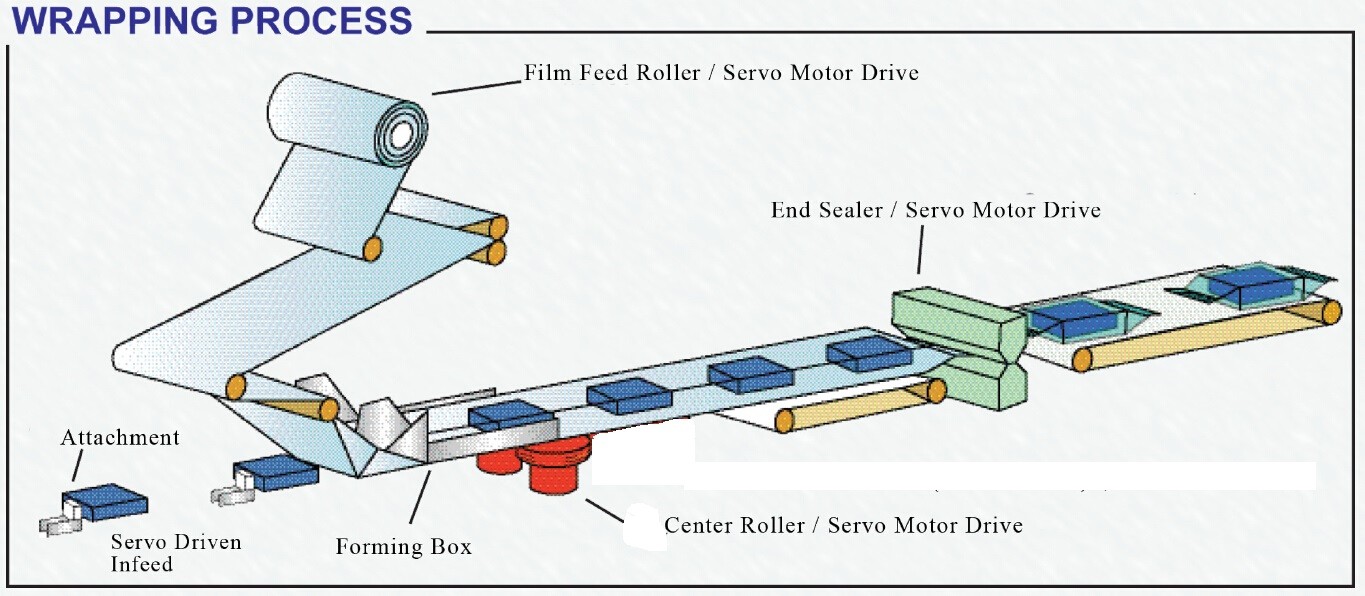

- Horizontal Flow Packing Machine(film-feed-from-bottom type)

- Min Order

- 1 piece

- brand name

- SANWEIHE

- model

- SWF-590

- Nearest port for product export

- QINGDAO, TIANJIN, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- update time

- Tue, 01 Sep 2020 14:06:59 GMT

Paramtents

sliver blue

Speed 20-120packs/min

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Single Piece product packaging:

Bread, chocolate en-robed cheese bar, soaps, Popsicle, cookies, waffle, trowel, cotton wool.

Group packaging:

Waffles, meat chops, bakeries, soaps, sponges, biscuits with tray etc.

Non standard products (customization):

Individual spoon, fork, knives, also suit for packing spoon, fork, knife, napkin, toothpick, etc.

|

Max film width |

590mm |

|

Packing Sizes |

L:50~600mm, W:20~200mm H:5~110mm |

|

Packing Speed |

30~150bags/min |

|

Packing material |

Poly film, Aluminum foil poly film |

Power Consumption | 4.7KW Single Phase 220V |

Machine sizes | LxWxH:5700×1050mm×1700mm |

Machine weight | about 1000kg |

Auxiliary equipment

1.Date code printer

2.Automatic feeder

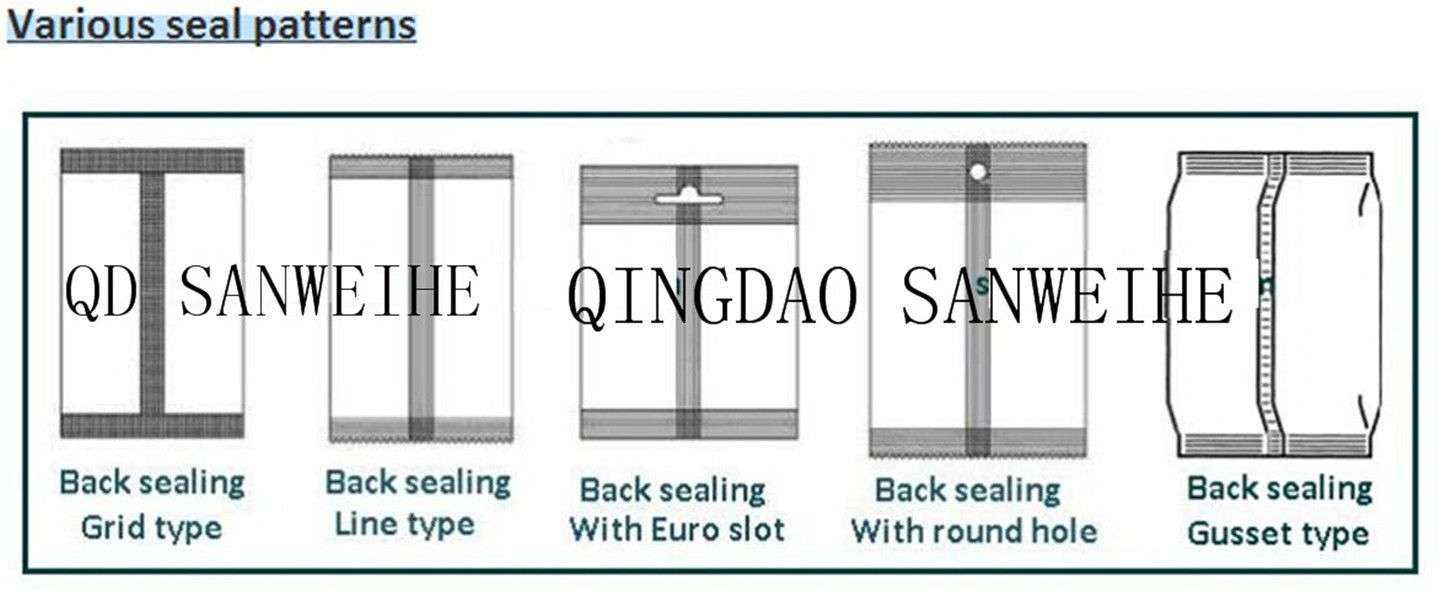

3.Euro slod or can be made

1.Adopting the PLC control for a more stable and reliable system with less trouble.

2.Digital display with packing length, speed and temperature adjustable separately, easy and accurate for use.

3.Two-way tracking for accurate sealing and cutting Position

4.The main technical parameter for film feeding from below flow automatic packing machine

1. We are manufacture but not trade company

2. We have professional staff who can advise you the suitable choice for your specific need

3. Our professional workers will make the perfect product for you

4. Well trained and experienced staff will answer your inquiry timely

5. We provide competitive price and fine quality products