SWSF-720 Reciprocating Type or D-cam Motion Packaging Machinery

- group name

- Horizontal Flow Packing Machine(normal type)

- Min Order

- 1 piece

- brand name

- SANWEIHE

- model

- SWWF-720

- Nearest port for product export

- QINGDAO, TIANJIN, GUANGZHOU

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- update time

- Tue, 15 Sep 2020 13:54:10 GMT

Paramtents

color silver and blue

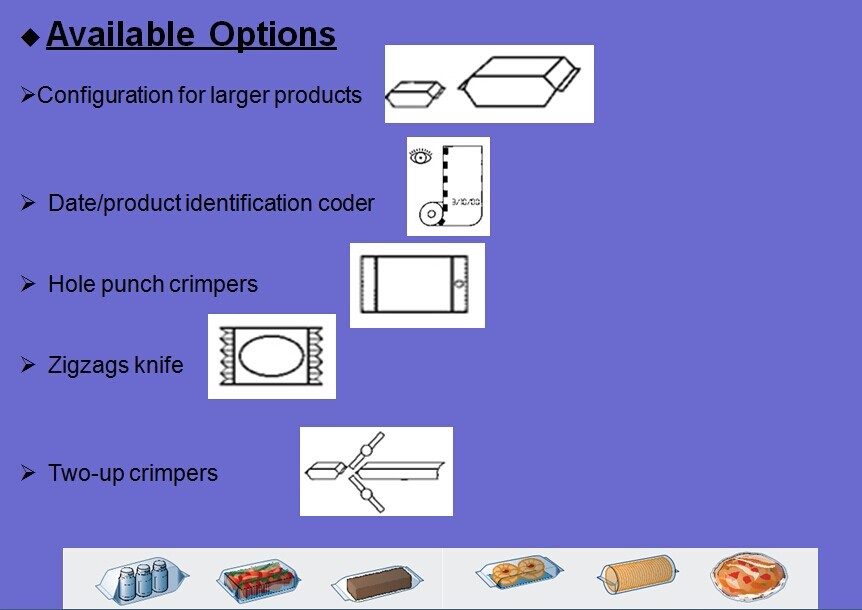

packing speed 20-100packs/min

OEM Service available

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

|

Max film width |

720mm |

|

Packing Sizes

|

L:50~600mm, W:20~200mm H:5~120mm |

|

Packing Speed |

30~80bags/min |

|

Packing material |

Poly film, Aluminum foil poly film |

Power Consumption | 4.65KW Single Phase 220V |

Machine sizes | LxWxH:6000×1150×1750mm |

Machine weight | About 1000kg |

1. Dual frequency conversion control, bag length can be set and cut in one step, saving time and film.

2. Human-machine interface, easy parameter setting.

3. Self failures diagnosis, clear failure displaying.

4. High sensitivity photocell, digital input of cutting and sealing position for extra accuracy, Precise heat controls with digital setting and out-of-range alarms assure consistent seal quality.

5. Separate temperature control, suitable for packing different materials.

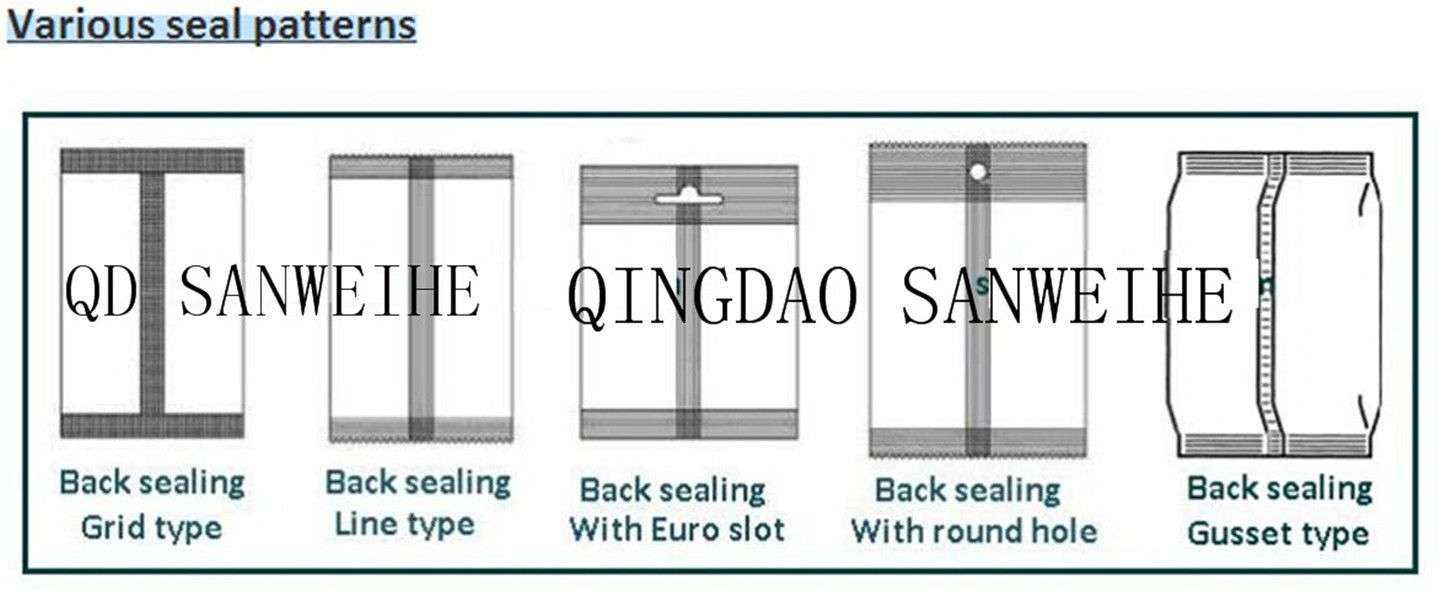

6. Reciprocating sealing(D-Cam motion profile will increase the maximum film sealing range by 15-20%) makes the seal firmer, without wearing the cutters.

7. Sealing with gusseting device makes the bag better looking, improving the product level.

8. Positioning stopping function, not adhesive to cutters and no waste of packing films.

9. Simple driving system, more reliable and more convenient maintenance.

10. All controlled by software, convenient for adjusting and technical upgrading.

1. We are manufacture but not trade company

2. We have professional staff who can advise you the suitable choice for your specific need

3. Our professional workers will make the perfect product for you

4. Well trained and experienced staff will answer your inquiry timely

5. We provide competitive price and fine quality products